House Solutions Made Easy

Element houses for development projects & private customers

References

Warning: Trying to access array offset on false in /data05/virt8112/domeenid/www.puumaja.ee/htdocs/wp-content/themes/puumaja/page-references.php on line 26

Warning: Trying to access array offset on false in /data05/virt8112/domeenid/www.puumaja.ee/htdocs/wp-content/themes/puumaja/page-references.php on line 26

Warning: Trying to access array offset on false in /data05/virt8112/domeenid/www.puumaja.ee/htdocs/wp-content/themes/puumaja/page-references.php on line 26

Warning: Trying to access array offset on false in /data05/virt8112/domeenid/www.puumaja.ee/htdocs/wp-content/themes/puumaja/page-references.php on line 26

How We Produce Our Houses

We produce factory-manufactured elements of wooden houses. Puumaja’s high standards of production are achieved with combination of experienced engineers and the use of high-quality raw materials in a controlled factory environment.

At Puumaja, we know that standard solutions are not suitable for everyone. That’s why we work closely with each of our clients to produce a unique, tailored design, matching in all specifications the needs of the customer. Whatever your requirement, we can accommodate it in our houses.

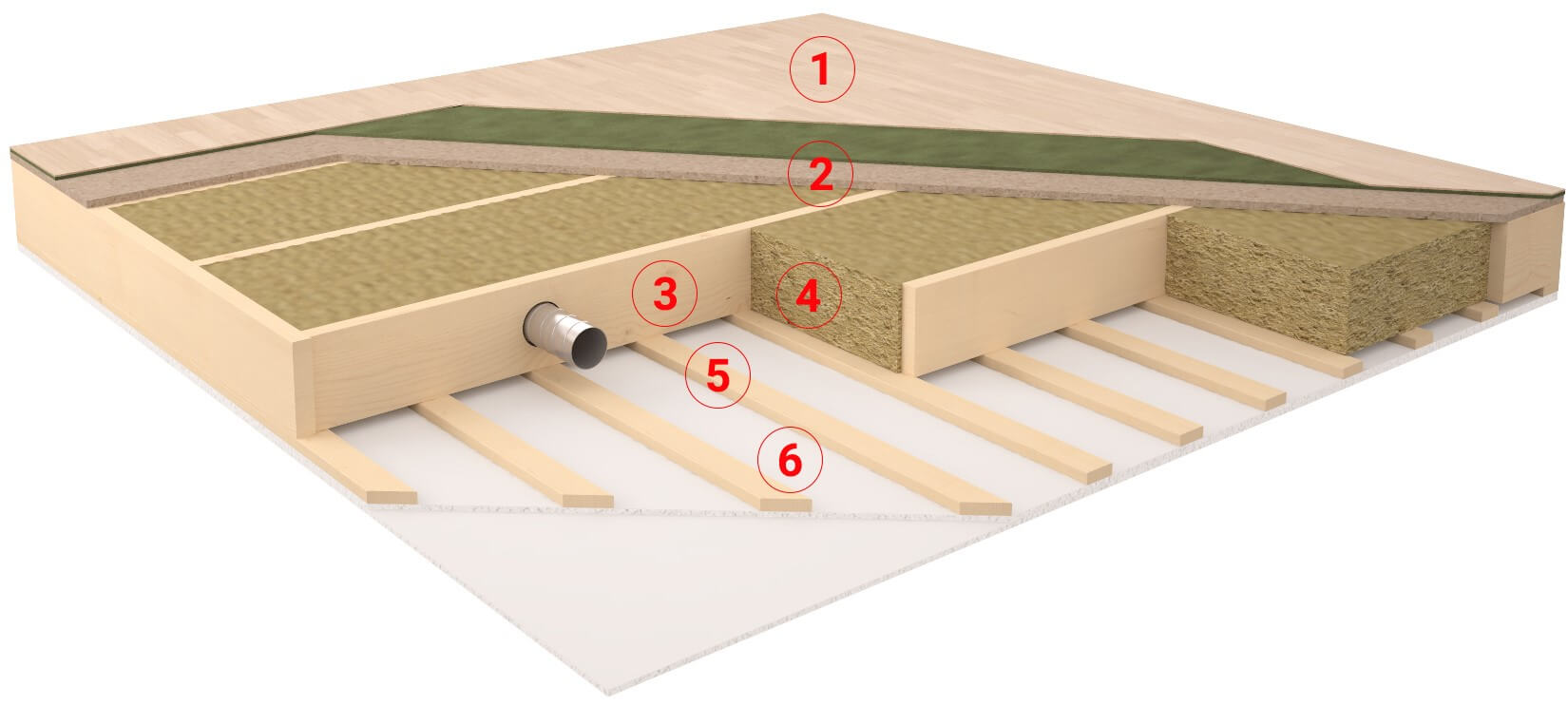

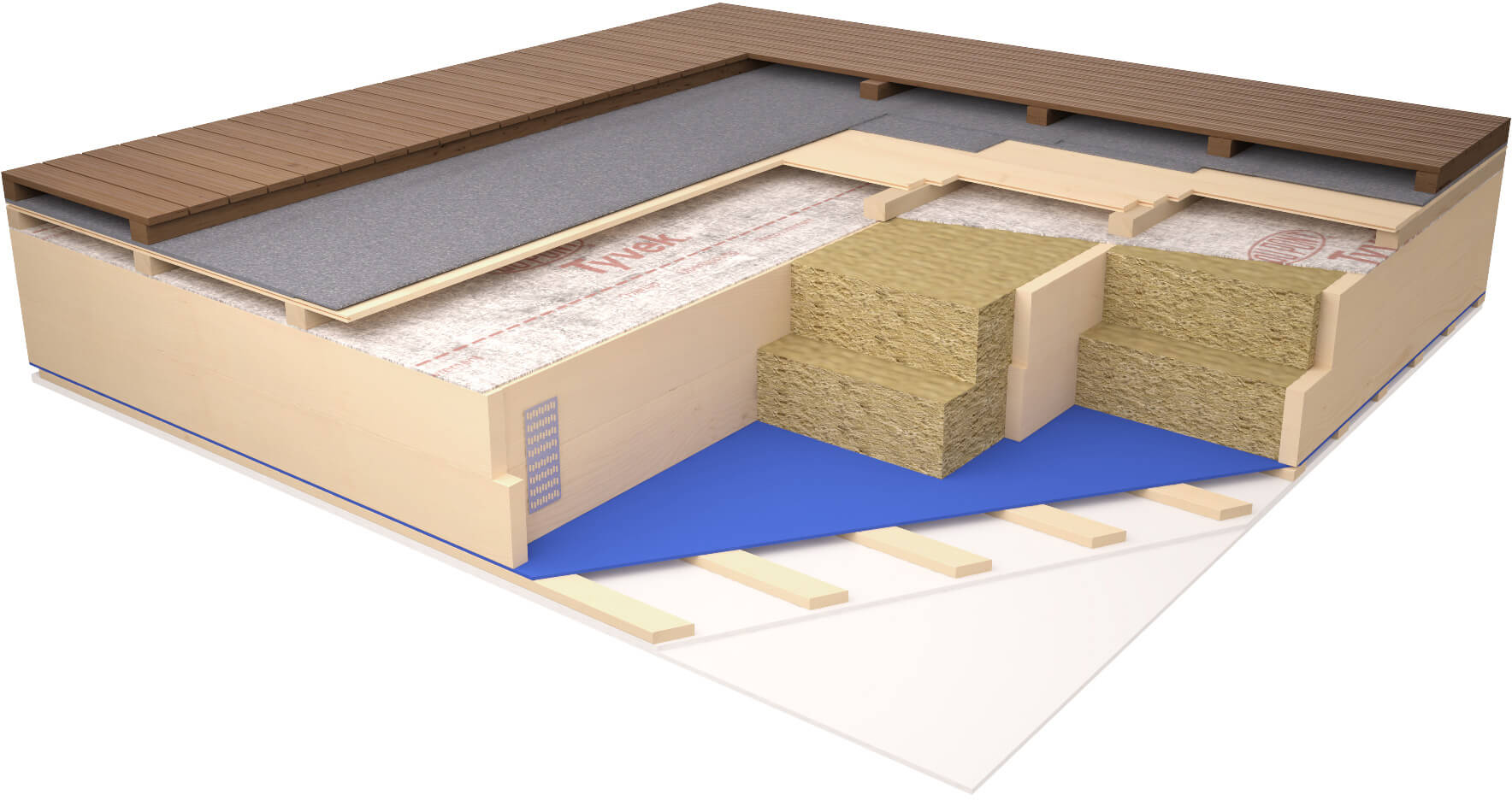

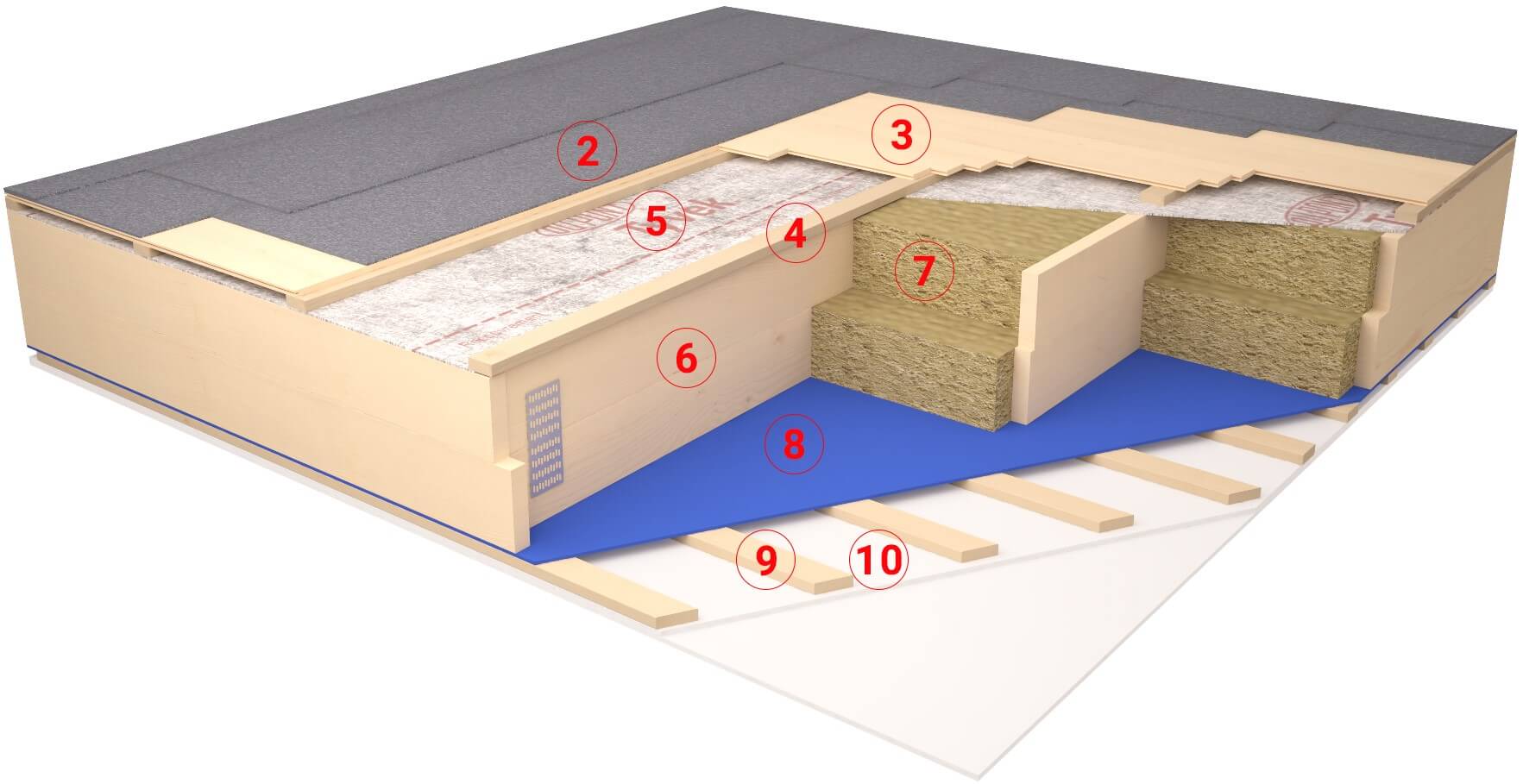

Floor- and ceiling element

Ceiling element – standard solution

- Final floor covering material (installed on site)

- 22 mm chipboard

- 45×220 mm wooden frame

- 220 mm insulation – glasswool or rockwool

- 28×70 mm laths

- 13 mm gypsum board (installed on site)

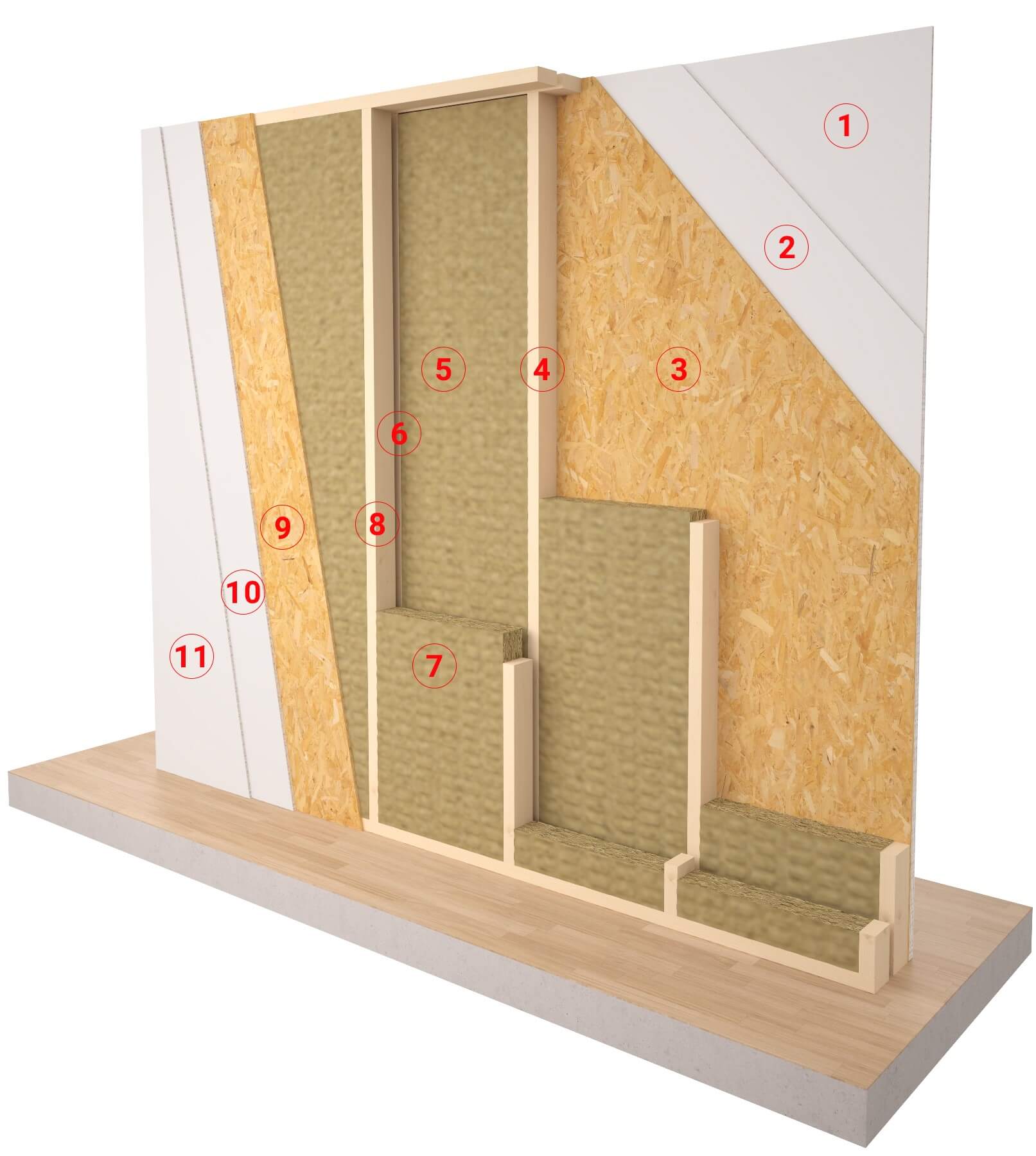

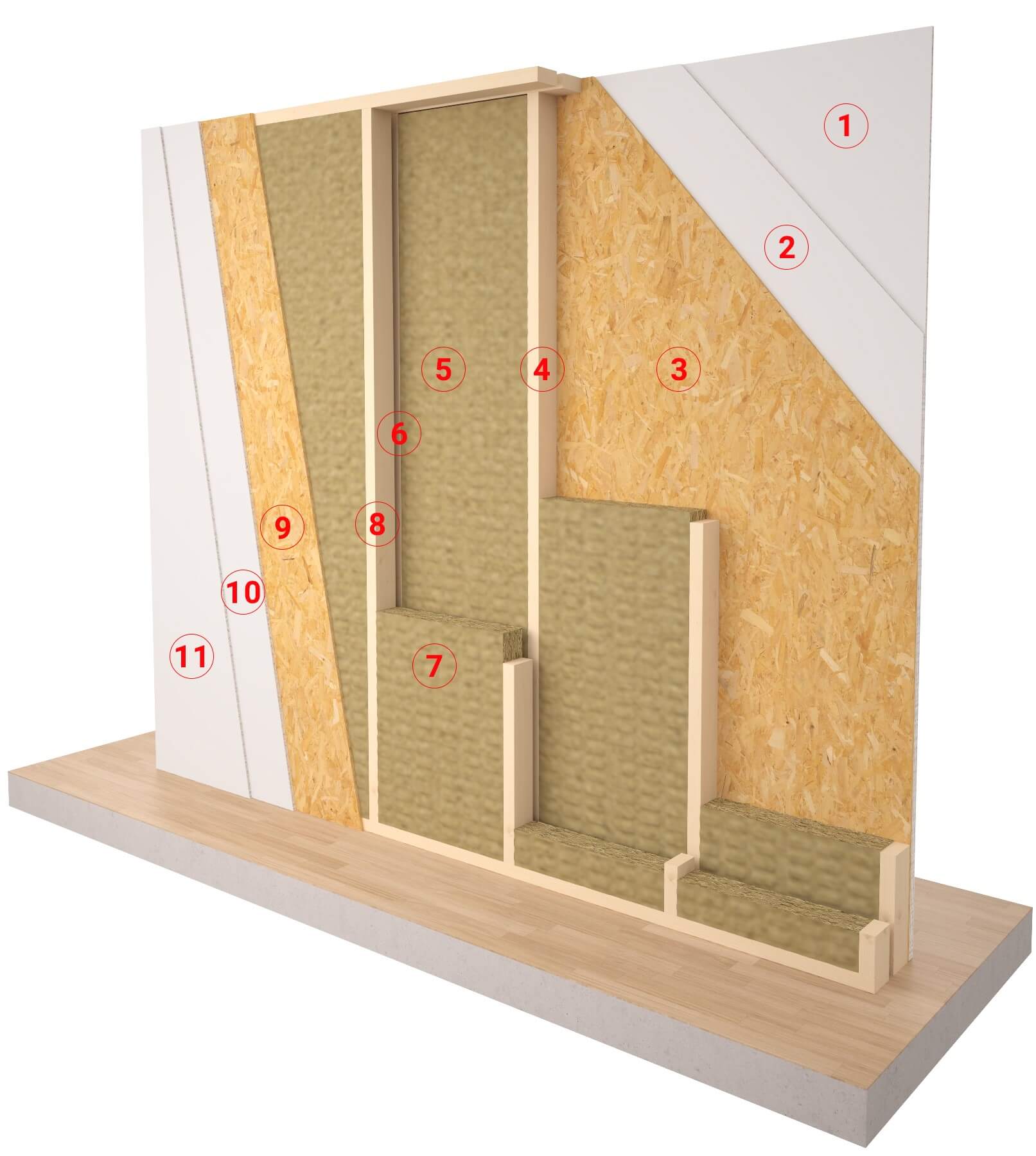

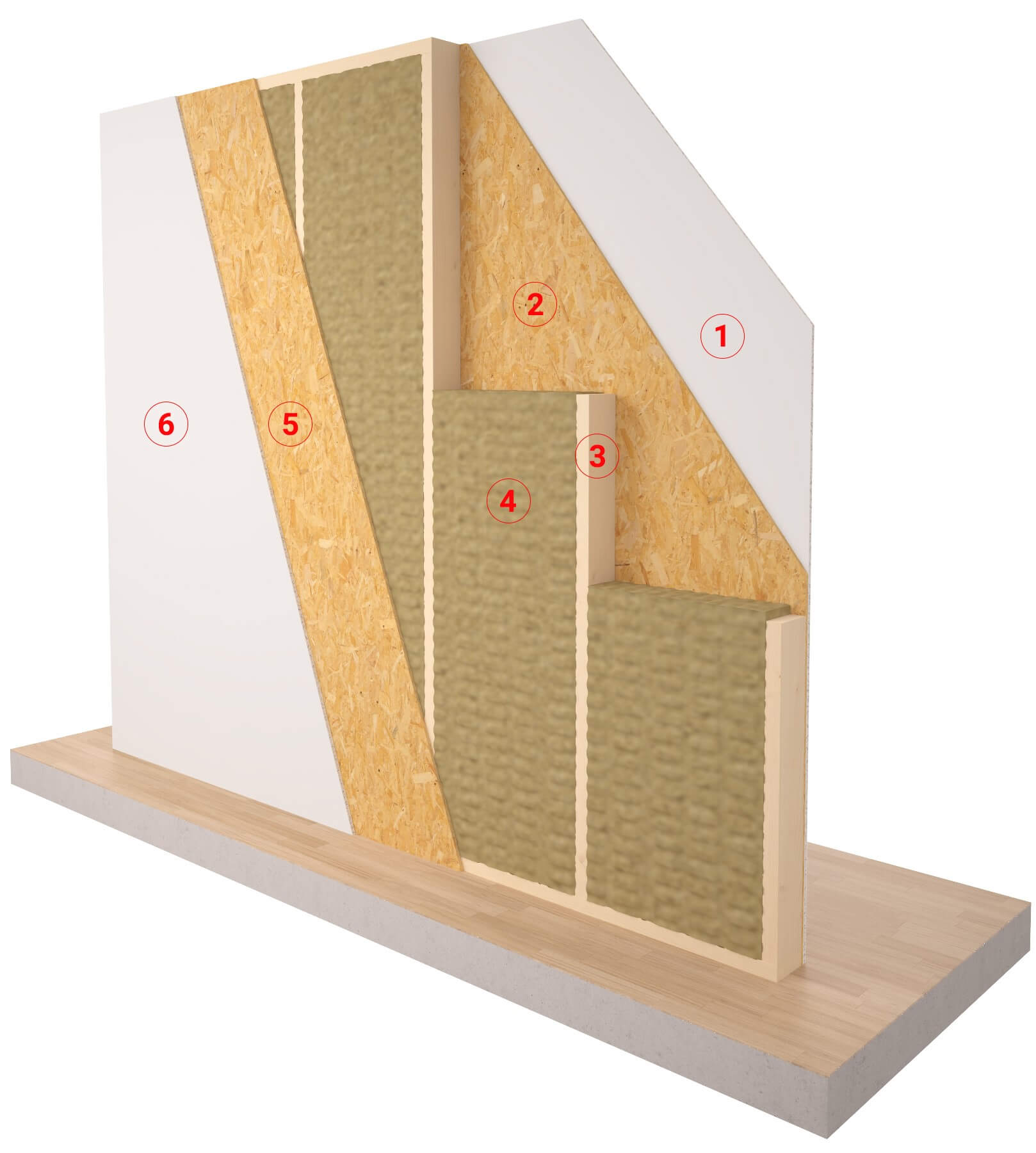

Apartment separating wall

Double walls between apartments – standard solution

- 15 mm Fire protective gypsum

- 13 mm gypsum board

- 12 mm OSB board

- 45×95 mm frame

- 100 mm insulation – glasswool or rockwool

- 30 mm gap

- 100 mm insulation – glasswool or rockwool

- 45×95 mm frame

- 12 mm OSB board

- 13 mm gypsum board

- 15 mm Fire protective gypsum

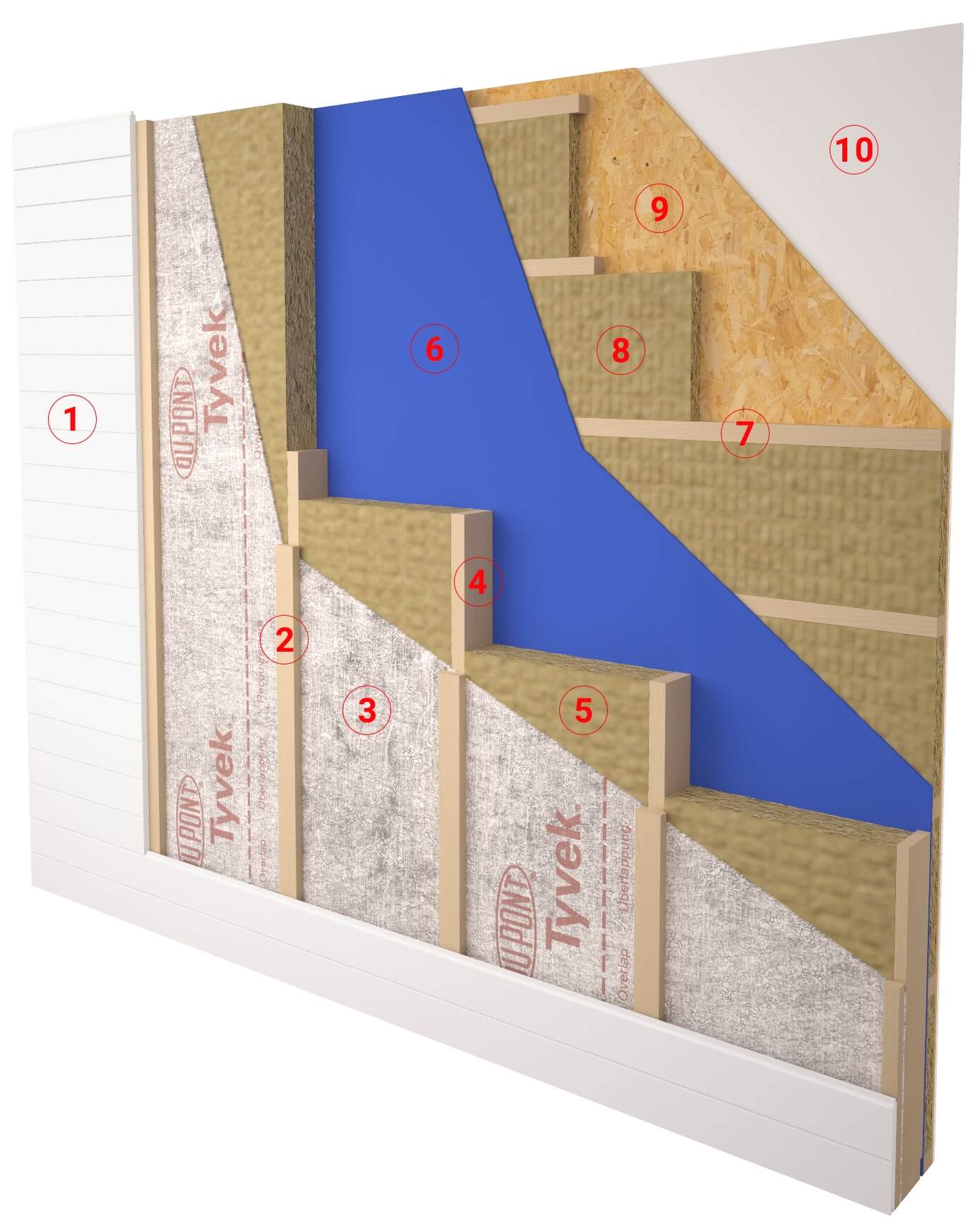

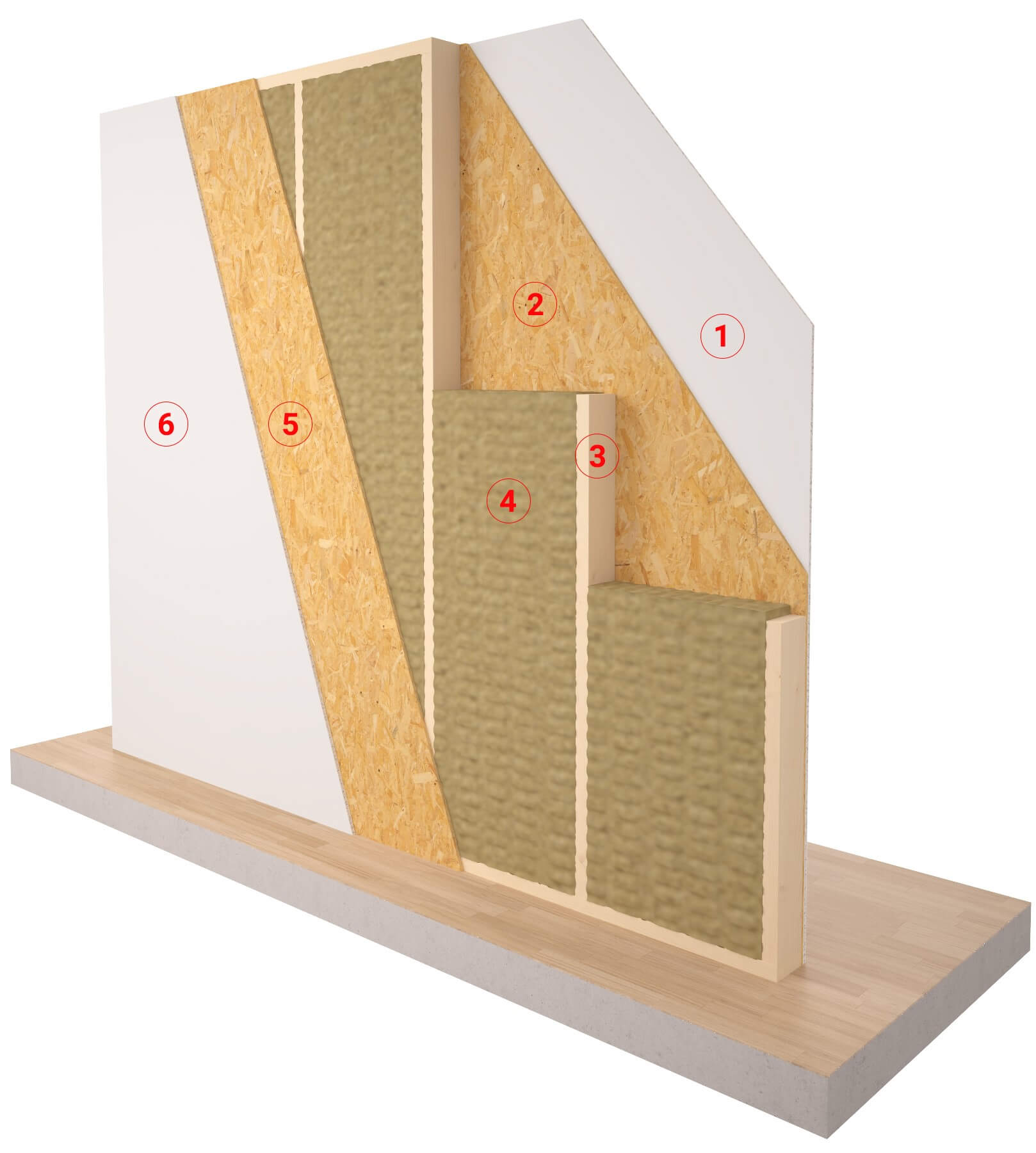

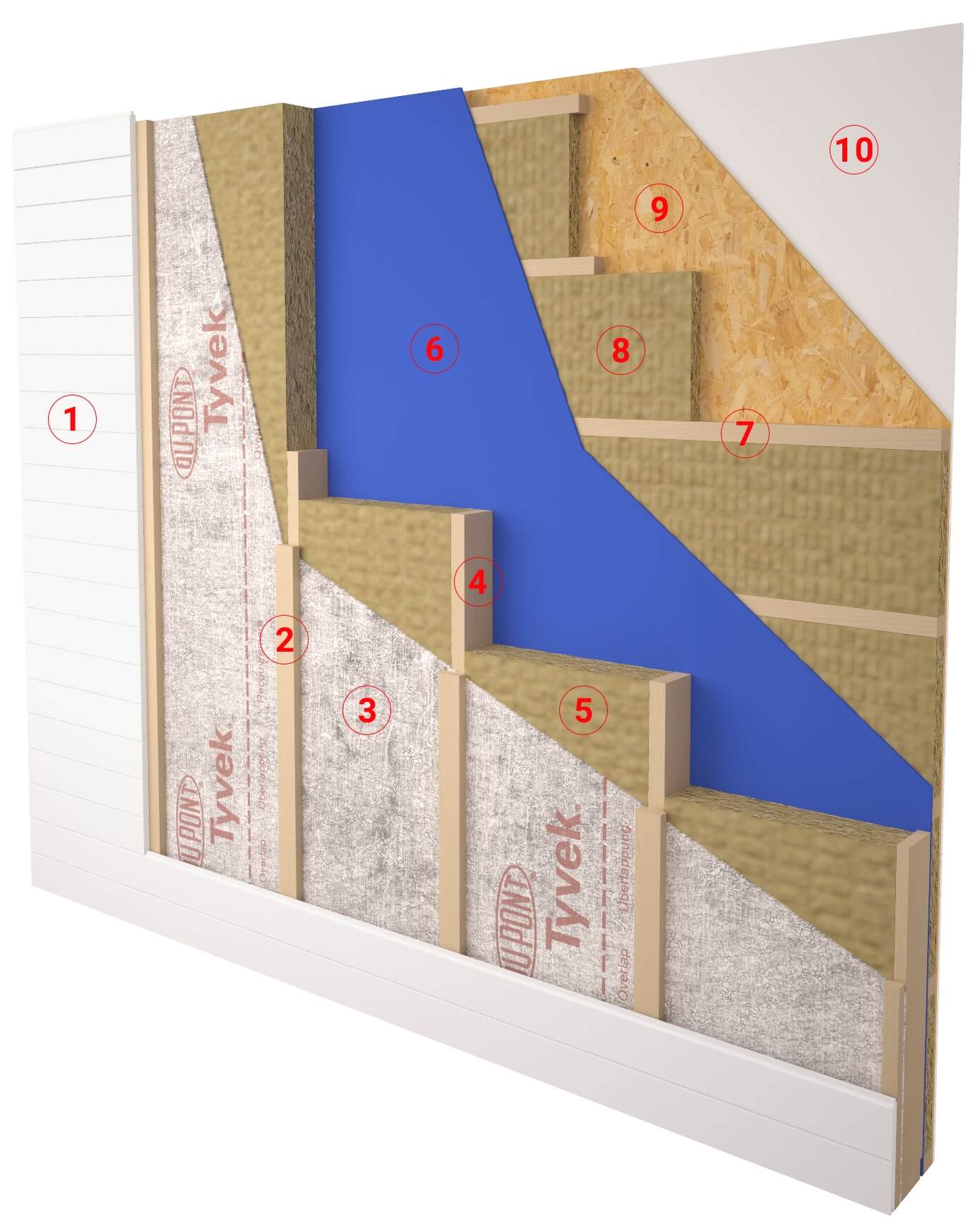

External wall

External walls – standard solution

- 22×145 mm Horizontal/Vertical outside panel, 1 x ground paint + 2 x paint

- 28×70 mm Horizontal/Vertical laths

- 9 mm climaboard

- 45×195/220 mm wooden frame

- 200 mm insulation – glasswool or rockwool

- 0,2 mm plastic age resistant vapor barrier

- 45×45 mm, cc 600 horizontal laths

- 50 mm insulation – glasswool or rockwool

- 12 mm OSB

- 13 mm gypsum board

Electrical boxes and pipes installed according to electrical design by customer – without cables.

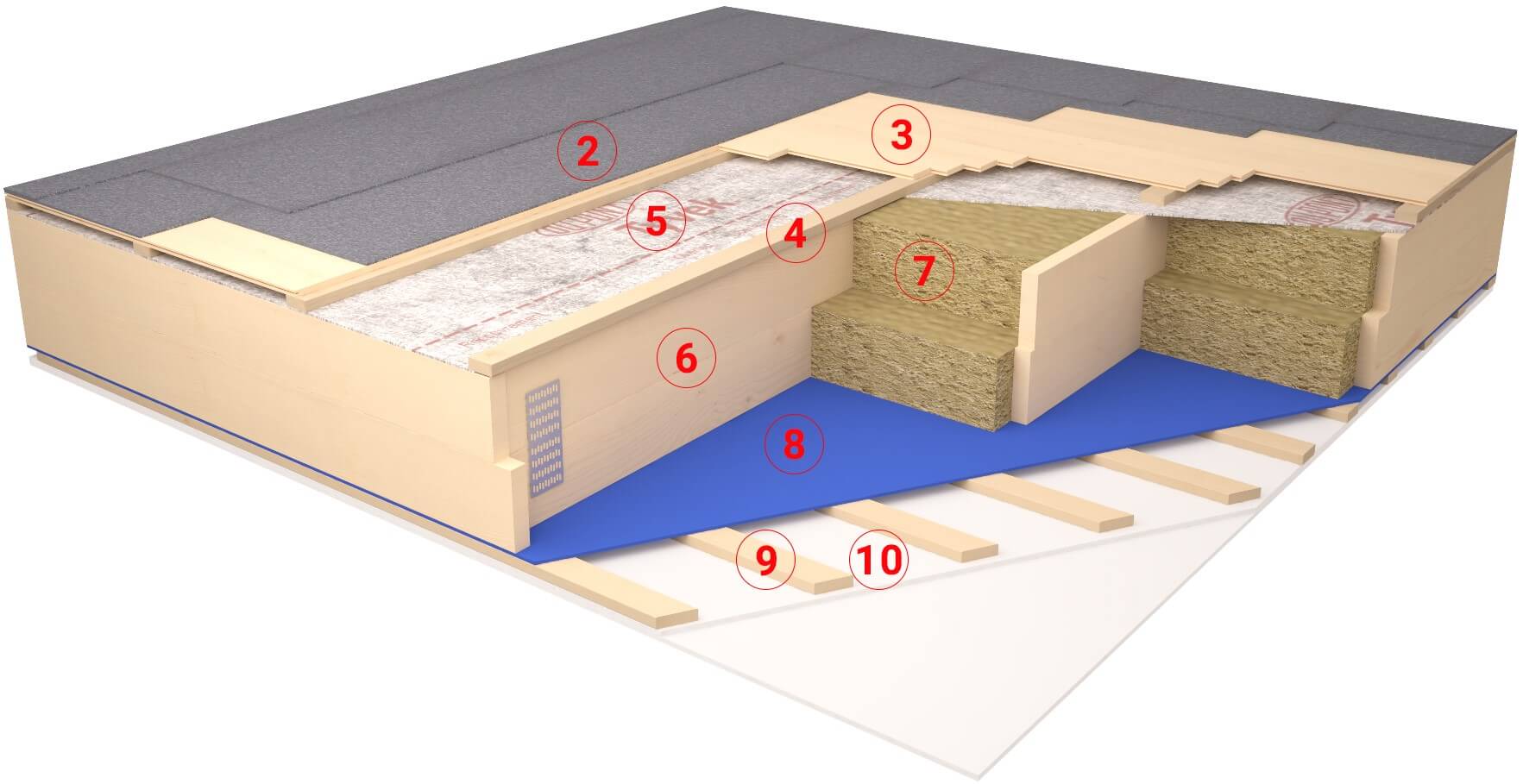

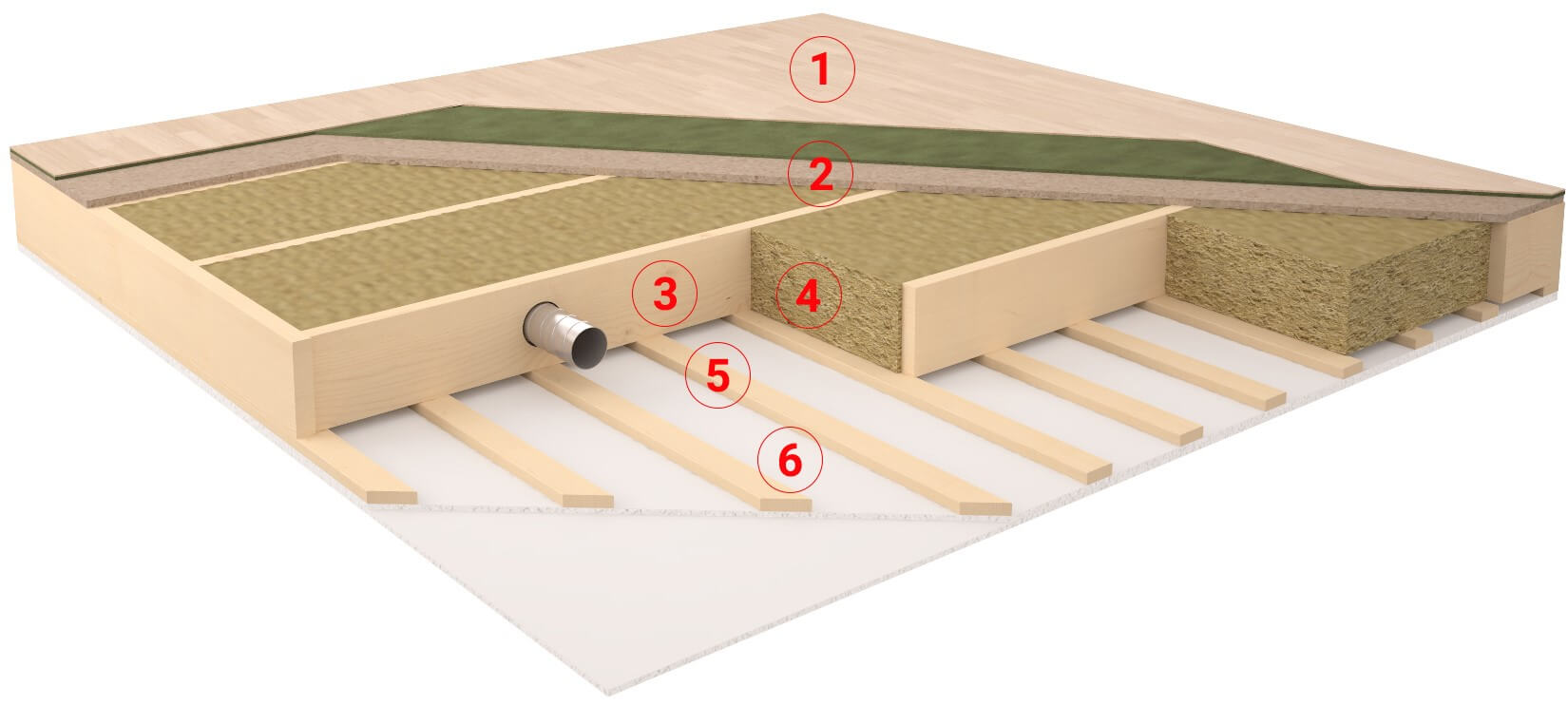

Roof elements

Ceiling element – standard solution

Final roof covering material installed on site

- YAP 2200

- 21×120 mm Raspont

- 45×45 mm laths for ventilation

- Tyvek wind protection

- 390 mm nail –plate double beams

- 400 mm insulation

- 0,2 mm AB folie

- 28×70 mm laths, cc 300

- 13 mm gypsum

Insect net in ventilation

Roof elements with balcony

Inside walls

Inside walls – standard solution

- 13 mm Gypsum board

- 12 mm OSB board

- 45×70 mm frame, cc 600 mm

- 70 mm insulation – Isover glass-wool

- 13 mm Gypsum board

- 12 mm OSB board

Floor- and ceiling element

Ceiling element – standard solution

- Final floor covering material (installed on site)

- 22 mm chipboard

- 45×220 mm wooden frame

- 220 mm insulation – glasswool or rockwool

- 28×70 mm laths

- 13 mm gypsum board (installed on site)

Apartment separating wall

Double walls between apartments – standard solution

- 15 mm Fire protective gypsum

- 13 mm gypsum board

- 12 mm OSB board

- 45×95 mm frame

- 100 mm insulation – glasswool or rockwool

- 30 mm gap

- 100 mm insulation – glasswool or rockwool

- 45×95 mm frame

- 12 mm OSB board

- 13 mm gypsum board

- 15 mm Fire protective gypsum

External wall

External walls – standard solution

- 22×145 mm Horizontal/Vertical outside panel, 1 x ground paint + 2 x paint

- 28×70 mm Horizontal/Vertical laths

- 9 mm climaboard

- 45×195/220 mm wooden frame

- 200 mm insulation – glasswool or rockwool

- 0,2 mm plastic age resistant vapor barrier

- 45×45 mm, cc 600 horizontal laths

- 50 mm insulation – glasswool or rockwool

- 12 mm OSB

- 13 mm gypsum board

Electrical boxes and pipes installed according to electrical design by customer – without cables.

Roof elements

Ceiling element – standard solution

Final roof covering material installed on site

- YAP 2200

- 21×120 mm Raspont

- 45×45 mm laths for ventilation

- Tyvek wind protection

- 390 mm nail –plate double beams

- 400 mm insulation

- 0,2 mm AB folie

- 28×70 mm laths, cc 300

- 13 mm gypsum

Insect net in ventilation

Inside walls

Inside walls – standard solution

- 13 mm Gypsum board

- 12 mm OSB board

- 45×70 mm frame, cc 600 mm

- 70 mm insulation – Isover glass-wool

- 13 mm Gypsum board

- 12 mm OSB board

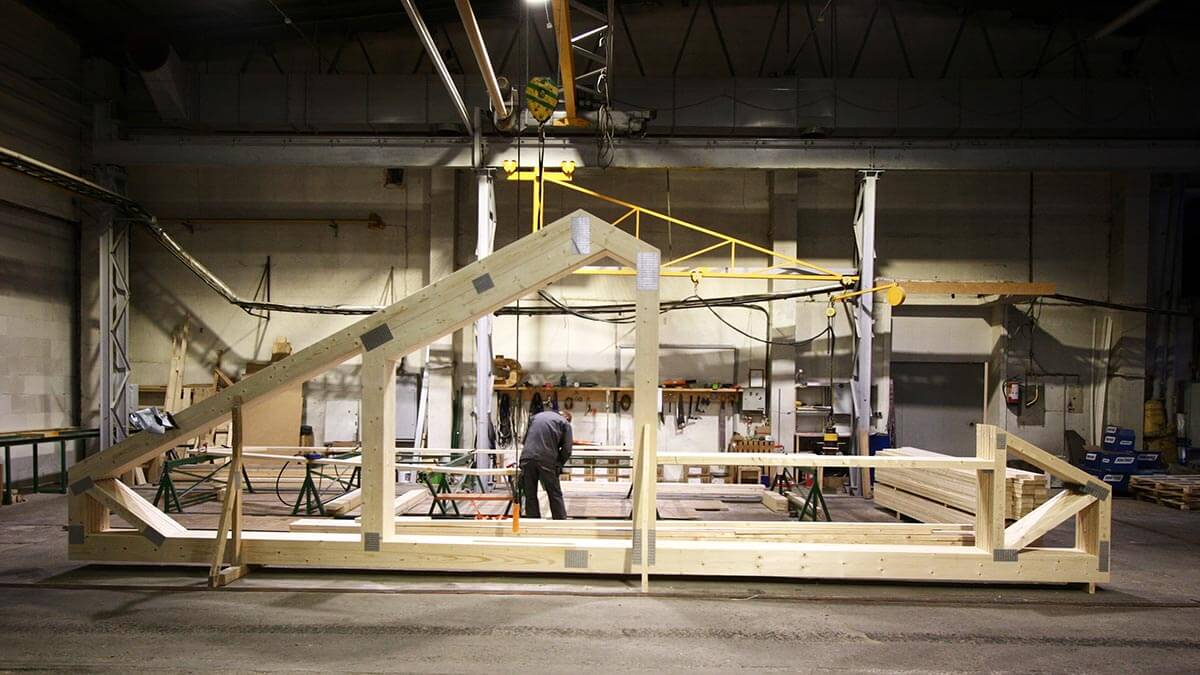

Factory

Technology Meets Efficiency & Quality

From private homes to development projects

- The possibilities are almost unlimited – we are able to produce buildings of all dimensions – from private homes to three-storey buildings.

- Both small and large projects are welcome – we are capable of producing anything from individual, tailor-made, houses, to whole villages, quickly and efficiently in our modern factory.

- A factory that is located nearby – production in Estonia, Europe’s largest exporter of wooden houses.

Certified quality at every stage

- A track record of engineering excellence – knowledge gained from the sharp end of building design and manufacture is put into practice, using engineering solutions you can trust.

- Technology-based precision – automation wherever possible, including accurate saws that are used to cut all the materials used in house elements.

- Factory-based production, independent from outside weather – all elements are produced in factory that features a controlled climate, proven as ideal for the production of timber house elements.

- Consistent and reliable processes – the standardised production process and internal quality control ensure consistency, the like of which cannot be achieved with on-site construction.

- An experienced team – everyone, from engineers to builders, are grounded in, and have worked for a long time with, Nordic standards.

We preserve nature and your budget

- In order to take care of the environment, we use only environmentally friendly materials that are supplied by reputable and recognised partners

- In order to benefit the client – building element houses is more economical and faster, which means lower costs for you

- Always a small step ahead – we always comply with, or even exceed, relevant international requirements

Premium-Quality Assembly Service

The durability of element houses is dependent not only on which building materials are used, or the quality of production. Precision assembly is also essential.

If you wish, we can provide comprehensive service – from production of the elements to professional construction.

- Assembly on the chosen construction site.

- Fully trained builders that are familiar with Puumaja production.

- Years of building experience in Nordic countries.

Building successful Partnerships

Consistent success is a result of commitment and reliable partnership. Contact us to discuss possibilities for cooperation.